Info Hub

Order Process

Our straightforward yet comprehensive order process ensures that your dream building is constructed on time.

1) Identify your requirements

Selecting your metal building entails a meticulous assessment of size, intended use, location, structural considerations, aesthetic preferences, and budget constraints. We encourage you to explore our products and choose whichever best suits your needs.

2) Customize your building

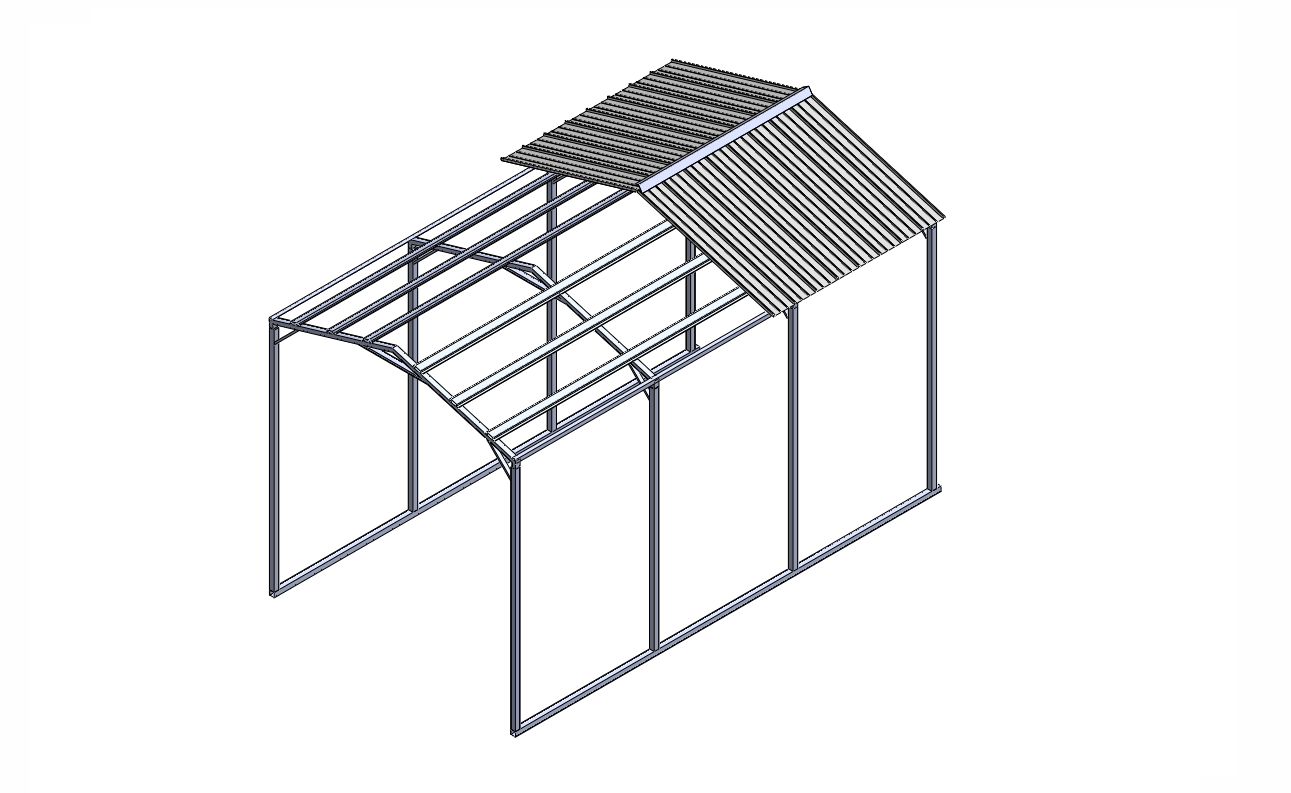

Use our 3D visualization tool to tailor every aspect of the structure to your precise specifications. With this technology, you can virtually visualize your project from every angle, allowing for a detailed exploration of design elements, such as size, shape, color, windows, doors, and additional features.

3) Placing your order

Ordering the metal building you desire for your property is hassle-free with Stellar Steel Designs. To place an order, you can easily connect with us at any time through our online contact form, via email, or by simply giving us a call and speaking with one of our experienced representatives.

4) Payment

To confirm your order and commence construction on your building, we only need an initial down payment, the amount of which will vary based on the total purchase price of the building. The remaining balance will not be due until the installation of your building.

5) Preparation prior to installation

Preparation prior to installation is crucial to ensure the successful installation of your metal building. You will need to comply with your local department to obtain any necessary permits. In addition, you'll need to remove any obstacles such as trees, bushes, rocks, or debris that may hinder the construction process or interfere with the placement of the building.

6) Delivery & Installation

Once your building is ready for delivery and installation, we will coordinate a suitable time for the delivery. If you have any more queries about installation, please contact us today. We are more than happy to answer any questions.

7) Reviews & Referrals

After the successful installation of their metal building, our delighted customers often become enthusiastic advocates, sharing their positive experiences with friends, family, and colleagues. We encourage our customers to provide referrals, endorsing our quality service and products to others seeking reliable metal building solutions.

Components and Colors

Components

Select a component above to identify it

Standard Colors

Hunter G

Barn Red

Burgundy

Ocean

Ivory

Sandstone

Tan

Black

White

Brown

Q Gray

P Gray

Galvalume

Clay

Premium Colors 15%

TOL Red

Colony

Gallery

Burnished Slate

Copper

Terminology

- Bow: A bow is a structural component crafted from square tubing, bent to shape the form of the metal building.

- Legs: The legs serve as vertical supports for the roof of the metal building, functioning similarly to structural columns. They determine the roof's height.

- Base Rails: The base rails are the structural elements that function as the foundation of the building, connecting to the legs to outline the size of the metal building.

- Anchors: Anchors are employed to firmly attach the base rails to the foundation of the metal building. Different categories of anchors are used depending on the terrain in which the metal building is being installed. Concrete anchors (for concrete foundation), rebar anchors (for gravel/soil), and mobile home anchors (for dirt/asphalt/soil) are used most frequently.

- Truss: Trusses are triangular structures supporting the roof, distributing the load evenly and providing horizontal stability to the structure. They bear the weight of the roof, ensuring its stability even during severe weather conditions.

- Braces: A brace is a component that connects from the legs to the bow, serving a structural purpose by increasing the rigidity of the metal building frame

- Roof: There are three different styles of

roofs,

- Platinum (Vertical)The Vertical roof style stands out as the optimal choice for challenging weather conditions. With the Vertical roof style, vertical panels are featured, ensuring that they run seamlessly from the peak of the roof down to the eaves. Consequently, heavy snow, rain, and debris effortlessly slide off the roof, enhancing its resilience.

- Luxury (A-Frame Horizontal)The A-Frame Horizontal roof design imparts a residential aesthetic to your metal building, resembling a peaked roof style. This configuration entails horizontal sheeting, hence the name "A-Frame Horizontal." Consequently, the ridges on the panels run horizontally, extending from gable to gable. This is a lower cost option with a residential appearance.

- Premium (Regular)The Regular roof style boasts a straightforward design that complements most properties. It stands as our most budget-friendly option without compromising on the quality and strength of steel. While it may be our most affordable choice, it still upholds high standards. The depicted curved roof is dependable, offering longevity comparable to that of the A-Frame Horizontal style and Vertical style roof models.

- Hat Channel: Light gauge steel framing members that are utilized for supporting roofs and walls.

- Metal Sheet Panels: These panels comprise the entire wall and roof areas of your metal building. Various sizes, thickness, and colors are offered to tailor your metal building according to your preferences.

- Ridge Cap Foam: Foam closures are dense foam rubber strips utilized to assist in sealing the gap between the roof panels

- Ridge Cap: The metal roofing ridge cap serves as the trim positioned along the roof's ridge, the highest point where two roof slopes meet.

- Eave Overhang: The eave overhang refers to the edges of roofing that protrude beyond the exterior walls of the main building.

- Gable Ends: A horizontal panel, mirroring the curve of the bows at both ends of the carport, extends from the top of the legs upward. Vertical installation of gable ends is available for an additional cost.

- Trim: There are six different types of

trim:

- L-Trim:L-trim is utilized as decorative trim on the ends and corners of both A-Frame Horizontal style and Regular style metal buildings.

- Box Trim:These are installed below the roof of A-Frame Horizontal style roof.

- Vertical Roof Trim:This trim is installed to cover the area of the eave overhang, enhancing the aesthetic appeal of your metal building

- Z-Trim:This trim is used to cover the overlap of the concrete foundation, also serving to prevent water from entering your metal building.

- J-Trim:J-trim serves as decorative trim installed beneath additional paneling on the sides of carports, and around walk-in doors and windows.

- Corner-Trim:Trim used on the corners of the buildings with vertical siding.

- Doors: There are three different styles of doors for your metal building, solid doors, diamond doors, 9-lite doors. Please use our 3D customizer to choose your own.

- Garage Doors: The corrugated steel sheet rolls up into a nest above the opening. This option is among the more economical choices and stands out for its exceptional durability.

- Windows: There are various styles and sizes to choose from for your metal building. Please use our 3D customizer to choose your own.

- Insulation: Insulation for metal buildings

can come in various forms, including fiberglass, foam board, or spray foam, and is

typically installed in the walls, roof, and sometimes the floor of the building. It

helps to keep the interior of the building warmer in cold weather and cooler in hot

weather by slowing down the transfer of heat through the metal surfaces. This can

improve energy efficiency, reduce heating and cooling costs, and create a more

comfortable indoor environment. We offer four different types of insulation to our

customers:

- Single Bubble (R6):Single bubble insulation is typically used in walls, roofs, and floors of buildings to help control temperature and improve energy efficiency. It is relatively inexpensive compared to other types of insulation and can be a good choice for certain applications where cost is a concern. However, it may not provide as much insulation as thicker, more expensive materials, so its suitability depends on the specific requirements of the building and the climate in which it is located.

- Double Bubble (R9):Double bubble insulation is more effective at insulating than single bubble insulation, but it is also typically more expensive. However, its increased insulation properties may make it a better choice for buildings in climates where more insulation is needed to maintain comfortable indoor temperatures and reduce heating and cooling costs.

- Fiberglass (R10):Fiberglass insulation is known for its fire resistance and sound absorption properties. It is relatively easy to install. Fiberglass insulation is also relatively inexpensive compared to other types of insulation, making it a popular choice for many building projects.

- Prodex (R16):Prodex is a type of insulation product that combines reflective foil with closed-cell polyethylene foam. It is designed to provide both insulation and a radiant barrier in a single product. Prodex insulation is commonly used in a variety of applications, including metal buildings, residential homes, and commercial buildings.

Warranty and Certifications

Features on most residential buildings (non-commercial):

Features on commercial buildings:

Coverage Area

Hover over a state to view its lead time

- Alabama

- Connecticut

- Delaware

- Georgia

- Indiana

- Maine

- Maryland

- Massachusetts

- Mississippi

- New Hampshire

- New Jersey

- New York

- North Carolina

- Ohio

- Pennsylvania

- Rhode Island

- South Carolina

- Tennessee

- Vermont

- Virginia

- West Virginia